Quick Inductance Meter

I needed an inductance meter and had already spent my months spending money so I couldn't simply buy one. I built one instead.

Luckily I had all the bits I would need to build the meter in the junk box.

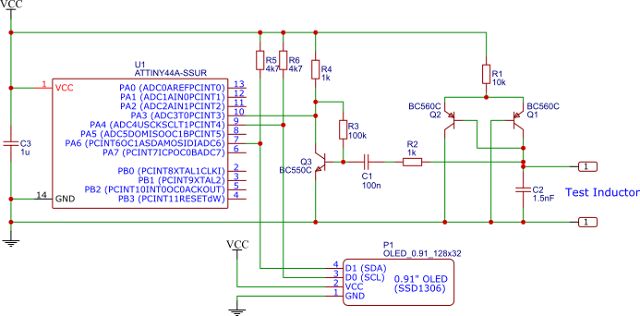

The circuit is very simple. Just an LC oscillator with a known tank capacitor. The micro counts the oscillator frequency and works out the connected inductance.

The formulae for the resonant frequency of the parallel LC tank is..

f = 1 / (2 * Pi * sqrt( L * C ))

Rearranged for L is...

L = 1 / (4 * Pi * Pi) * C * ( f * f )

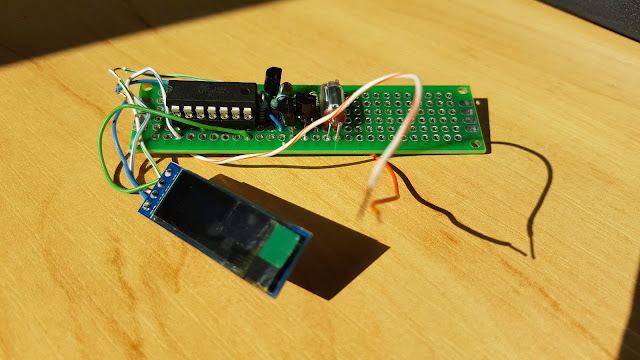

The circuit was cobbled together on a bit of board...

Whoops, n00b, lol.

Clamp, clamp.

Then Clamp some more...

I was stressing about powering the thing off a 1.5V battery, but I had a 9V battery and the case takes a 9V battery so I used an XC6202 3V linear regulator to power it.

I added a power button which briefly powers up the device, does a reading and then switches its self off after 10 seconds.

The circuit as built looks like this...

Source code and hex file are available here

The meter measures from 1uH to 10mH.

And a quick video showing the operation.

Making that video put me over the budget for this quick project, I had to buy a holder for my camera.

Clamp, clamp.

Then Clamp some more...

Fixed, nice label :)

I was stressing about powering the thing off a 1.5V battery, but I had a 9V battery and the case takes a 9V battery so I used an XC6202 3V linear regulator to power it.

I added a power button which briefly powers up the device, does a reading and then switches its self off after 10 seconds.

The circuit as built looks like this...

Source code and hex file are available here

The meter measures from 1uH to 10mH.

And a quick video showing the operation.

Making that video put me over the budget for this quick project, I had to buy a holder for my camera.